High performance your patients can depend on.These tests prove it.

As an ISTA member, we’ve validated our pack-outs to meet the precise thermal specifications that our clients require. We’ve logged over 1,000,000 hours of testing for the largest brands in perishable shipping.

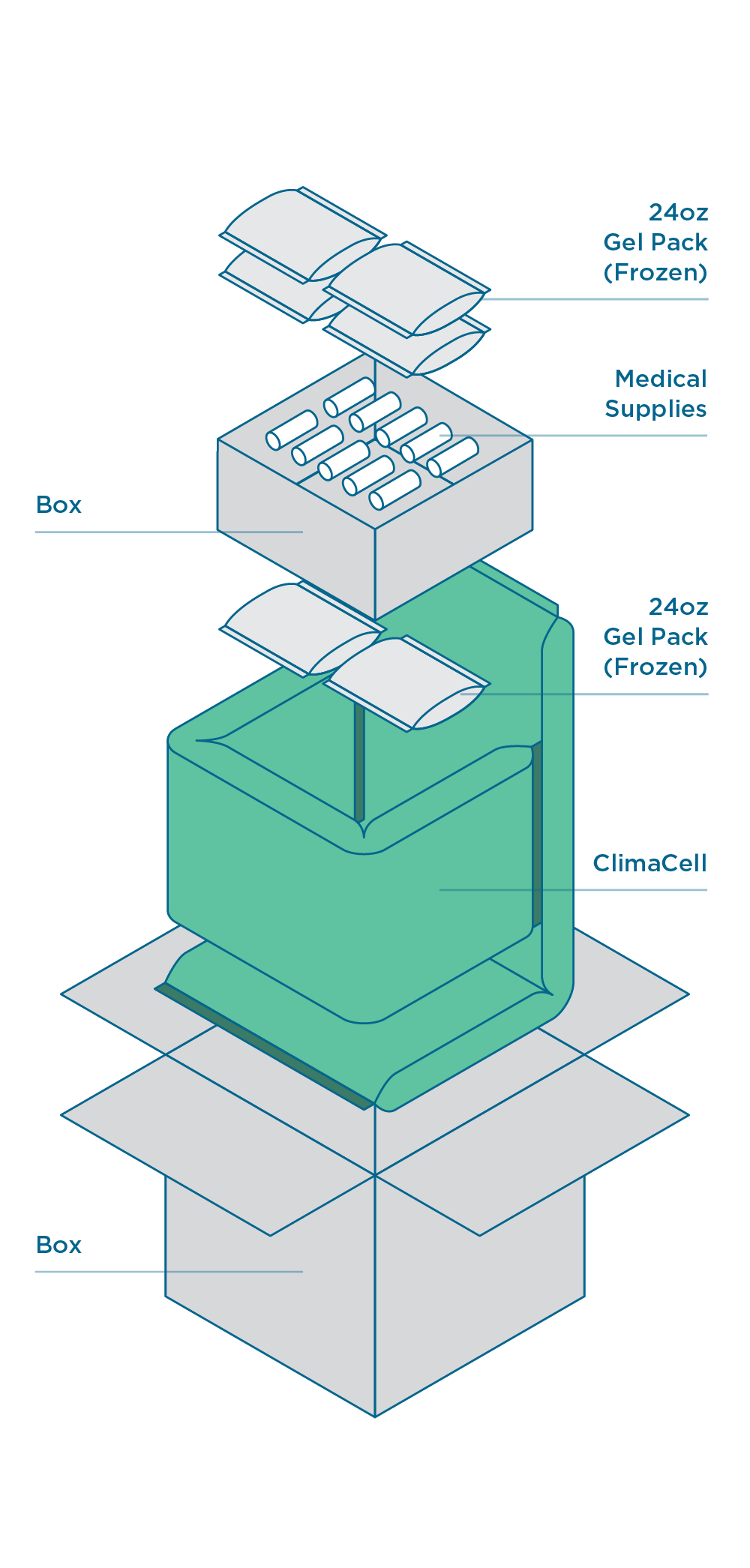

Test Details

| Box Dimensions | 13.625″ x 11.125″ x 12.25″ |

| Insulation | 2-PC ClimaCell | 1.5″ Thickness | 28-OPSY |

| Coolant | (6) 24oz Gel Packs |

| Payload | (10) 100mL Glass Vials |

| Profile | ISTA 7E Summer Test performed in SM-32C and SM-16C Thermotrons using TR-71WF temperature loggers |

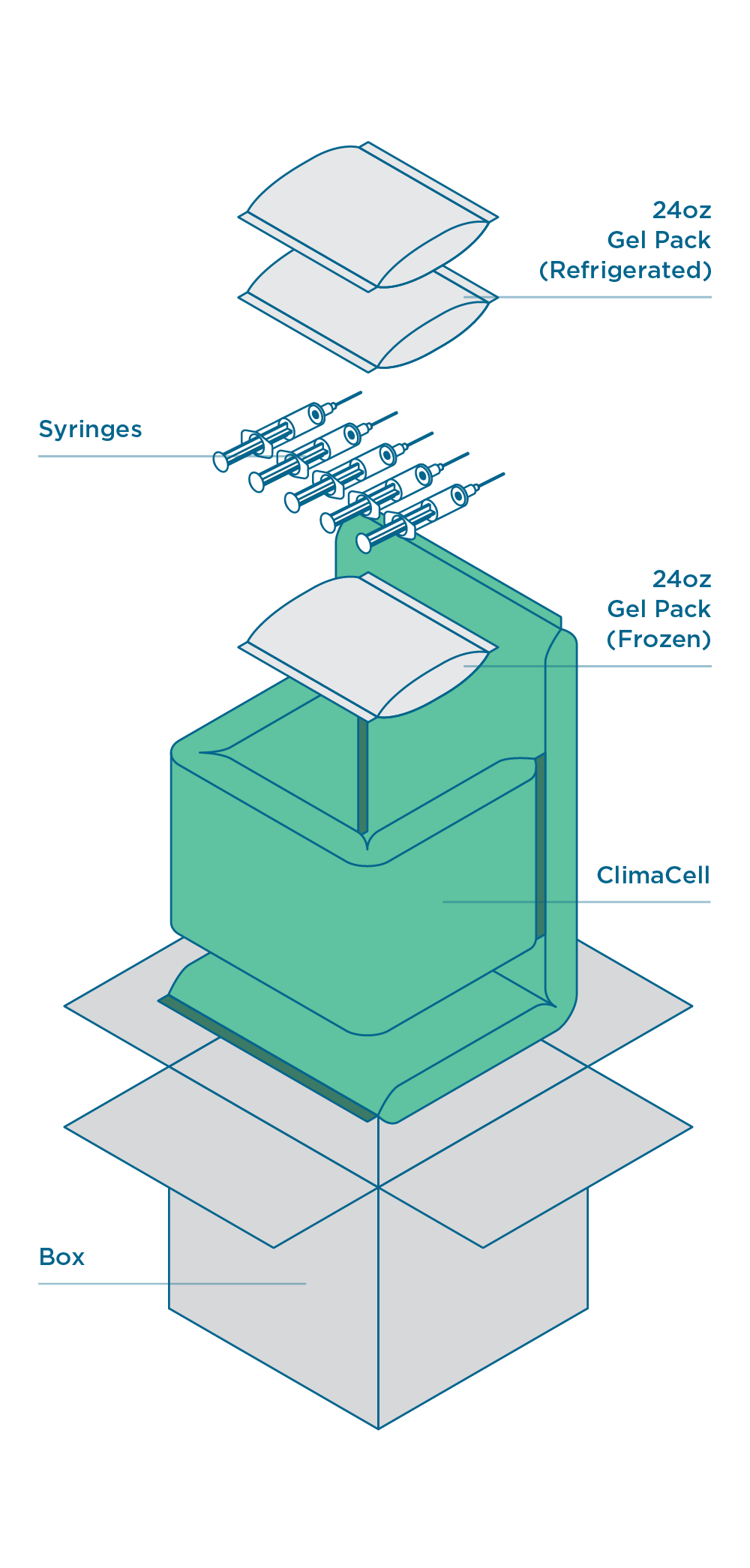

Test Details

| Box Dimensions | 11″ x 9″ x 12″ |

| Insulation | 2-PC ClimaCell | 1.5″ Thickness | 28-OPSY |

| Coolant | (2) Refrigerated 24oz Gel Packs (1) Frozen 24oz Gel Pack |

| Payload | (5) 10mL Syringes |

| Profile | ISTA 7E Winter Test performed in SM-32C and SM-16C Thermotrons using TR-71WF temperature loggers |

Ready Engineered Solutions

If you think retesting is a hassle, think again. We have a fleet of ready-engineered solutions that meet your shipping criteria.

Case Study:

New England Biolabs wins big by replacing Styrofoam.

New England Biolabs® wanted to reduce its environmental impact by replacing Expanded Polystyrene Foam, or “EPS,” (or more commonly known as Styrofoam®) as the packaging insulation for shipments of its valuable reagents used in life science research.

While sustainability was the main driver for making the change, NEB® was also hoping to see some gains in terms of operational and economic efficiency.

The Action

The New England Biolabs team and the TemperPack team worked together to understand the efficacy of its existing pack-out and develop a custom solution using ClimaCell thermal liners.

Result 1

The new validated pack-outs using ClimaCell maintained safe temperature longer than their previous pack-outs using EPS.

Result 2

Working with TemperPack engineers, NEB consolidated two cooler sizes into one, which created significant operational efficiencies.

Result 3

By replacing the majority of their shipments with recyclable ClimaCell, NEB was able to reduce the time spent processing EPS coolers that are returned to their facilities.

ClimaCell features yourpatients will love.

Unlike EPS, ClimaCell folds flat. This cuts down on shipping costs, takes up less space in recycling bins, and gives you back precious floorspace.

We can print your logo on ClimaCell products to boost your brand and promote your efforts in sustainability (with specific quantities).

100% of our materials can be traced back to the forests they came from. With traceable, raw materials you get peace of mind in every packout.

Our ClimaCell liners are fully curbside recyclable and we can even help to redesign your packout to make it completely recyclable, too.

Sustainable. Affordable. Controlled.

ClimaCell is made from renewable plant-based components. With excellent thermal performance and a competitive cost structure, it is the ideal replacement for unsustainable insulators, like Styrofoam®.

Work With Us

We’ve helped dozens of companies reduce their packaging costs and lower their overall impact on the environment. Give us a shout and we’ll work with you to develop a solution that suits your shipping needs.

Have Feedback?

Our clients ship millions of our sustainable liners every month. In order to continue to make a better product, we’d love to hear from you. If you received a shipment with a ClimaCell liner in it, let us know how your experience was.