The Short of It

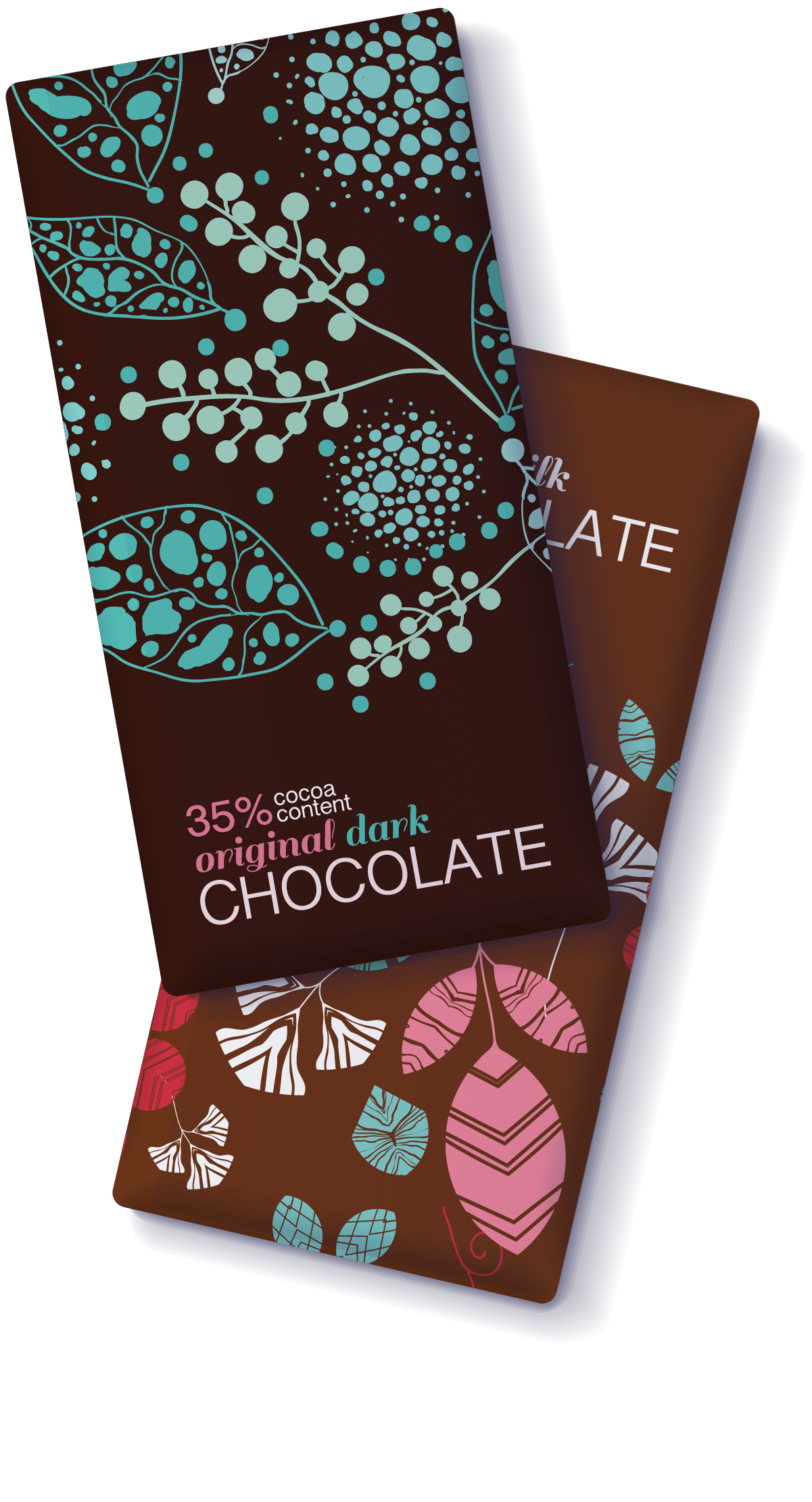

If you’re in the business of premium chocolate, whether you know it or not, you’re also in the business of thermal logistics. Getting your product to your customers’ homes in perfect condition requires a precise combination of insulation and coolant to prevent blooming, which occurs when chocolate gets too hot or too cold.

Want to learn more?

Read the full article below, or simply contact us.

Diving In

The US chocolate industry is expected to surpass $20 billion by 2025, with more and more companies entering the landscape. But as chocolatiers strive to grow, they’re realizing that success isn’t only based on creating the best product. It’s also about offering that product to their consumers where they want to buy it, which is increasingly online.

To build a strong e-commerce business for chocolates and confections, you need packaging that will stand up to the rigors of the supply chain and provide an at-home unboxing experience worthy of your premium brand.

Blooming is the enemy

Most chocolate wants to be 60-70°F. To delight your customers, you want your shipment to maintain that temperature range throughout its journey. When shipments get too hot or too cold, blooming happens.

Blooming is a term for the white, splotchy spotting appearing on chocolate that has been subject to improper fluctuations in temperature and moisture. With blooming, both visual appeal and texture can deteriorate.

There are two types of blooming: fat bloom and sugar bloom.

Fat Bloom

Fat bloom happens when the chocolate has melted and re-hardened due to temperature increases, which is typically beyond 80 to 90 degrees F, depending on the type of chocolate.

Sugar Bloom

Sugar bloom occurs when the chocolate is exposed to moisture, which can develop when the temperature drops too quickly to refrigerated temperatures.

Both types of blooming can spell doom for an overnight or two-day shipment, but they can be prevented. Here’s how:

Get the Insulation Right

The purpose of insulation is to slow down the transfer of energy from one space to another. Your choice of package insulation will have an impact on transit time, the amount of coolant you’ll need, and the size of box required.

Insulation will likely be your biggest packaging expense in your pack-out. There are many types of insulation materials available: expanded polystyrene foam, often known as Styrofoam®; cotton fiber liners; starch-based foam; bubble wrap; and recycled paper liners.

Here at TemperPack, we think our ClimaCell liners offer the best insulation on the market, especially for premium shipments. Our liners offer high levels of thermal performance and a sturdy structure for ease of use in your fulfillment facility.

Our insulation also uses kraft paper encapsulation, which creates an inviting unboxing experience for your customers at home. Paper signals quality, and people at home know it’s a more sustainable material than plastic. And ClimaCell liners are easily recyclable, so you’re not placing a burden on them to figure out what to do with the packaging you send them.

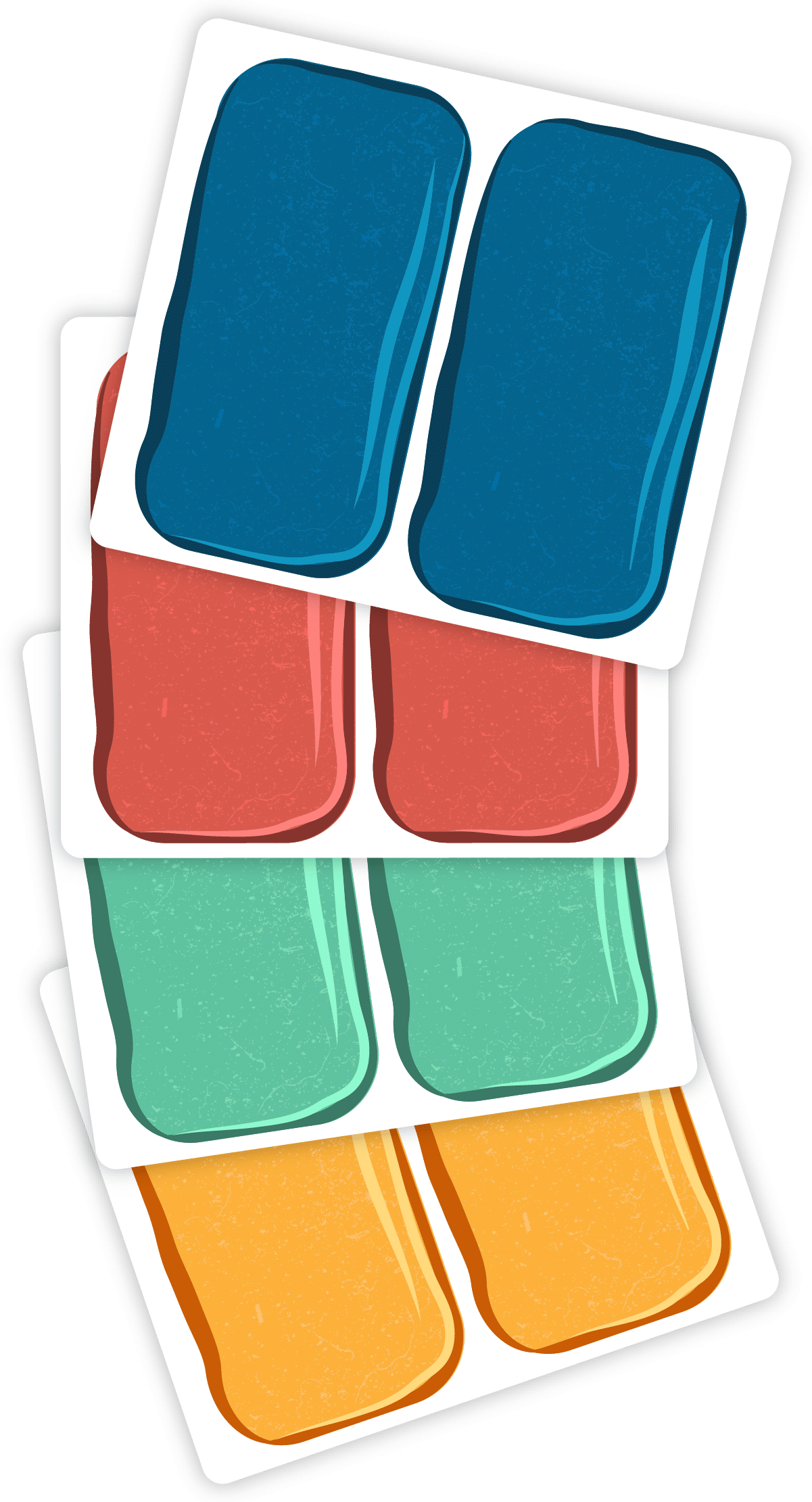

Be Smart About Coolant

In warmer climates or summer months, coolants can absorb the excess energy that is transferred from outside the box. In colder situations, coolants can expel that excess energy to maintain the optimal temperature for chocolate.

Coolant materials typically rely on their phase change to maintain a desired temperature. For example, water-based ice packs are a very effective material when trying to maintain temperatures close to 32 degrees F, the freezing point of water. However, water-based coolants are less effective when keeping temperatures that are much higher or lower than 32 degrees. PCMs, or phase change materials, are another possible high-performance option that can maintain temperature over a wider range of temperatures for longer durations.

Be Real about Your Primary Packaging

Primary packaging, which refers to the packaging materials used to directly contain your product, needs to match your brand experience, regardless of where it’s sold. When packaging chocolate for e-commerce purposes, it’s important to ensure that the primary packaging is sturdy enough to stand up to a shipment through trucks and warehouses. Sometimes the primary packaging you may use for retail might not be sturdy enough for the rigors of FedEx and UPS.

It’s also important to recognize that condensation is likely going to happen at some point in the shipment. If your primary packaging is built for presentation more than function, you might want to consider some kind of wrap in addition to the insulation to protect it.

Factor in Seasonality

As the seasons change, the amount of coolant and thickness of insulation can and should change as well.

It’s not just about melting: cold temperatures can have just as much of a negative impact on your chocolate as warm temperatures.

By staying in touch with conditions throughout your logistics chain, you can adjust your packaging accordingly to maintain quality. The right choices on your end will lead to a delicious experience for your customers.

Let's talk

Every company has its own unique specifications, based on their geographic footprint and preferred shipping criteria. Reach out or check out our lab page to learn more.

Jed Dutton

Jed Dutton is the Vice President of Marketing at TemperPack. Jed has spent his career bringing marketing strategy and creative execution together to help brands grow. His email address is [email protected].

February 1, 2024

Cytiva and TemperPack: Pioneering Biotech’s Sustainable Packaging Revolution

In the biopharma industry, bold thinking and rigorous precision are needed to create new innovations for a healthier society. Cytiva is leading the field by forging a path towards…

January 4, 2024

Caroline’s Cakes and TemperPack: A Recipe for Sustainability

Caroline's Cakes, a staple in the Southern culinary scene, celebrated by Oprah, and Stephen Colbert, has partnered with TemperPack to reduce its environmental impact and improve…