A really good idea will tend to haunt you.

At TemperPack, discovering those ideas is our job. The Nobel prize-winning Hungarian scientist Albert Szent-Györgyi once stated that, “Discovery is simply seeing what everyone else has seen – but thinking what no-one else has thought.”

In 2015, upstart meal-kit companies were faced with a major packaging problem. They needed to figure out how to send millions of boxes of fresh food to houses across the country each week – without using Styrofoam coolers to keep items cold.

This is when (and why) we started TemperPack.

Our first discovery was jute – a natural fiber grown in South Asia but cheaply available in the US in the form of discarded burlap bags used for coffee and cacao imports. We also discovered that bedding and felt companies in the US had available capacity due to the rising popularity of foam mattresses. We connected the dots and started making thin, compostable insulation blankets from 100% recycled jute fibers. We pitched this as a new type of packaging that was highly insulating, flexible, plant-based, cushioning – and available at a low cost. The idea caught on and from 2015 to 2018, TemperPack manufactured and sold tens of millions of pounds of plant fiber packaging insulation. During this time, we also developed and commercialized PopBox, which allowed customers to replace millions of non-recyclable bubble foil liners with a fully recyclable, paper-based box liners.

We were in business...

but we weren’t totally comfortable (and I hope we never are).

We constantly asked our customers to imagine better versions of our products. What would it look like? What would it allow them to do more effectively? They told us that a better version of our plant fiber insulation would be compatible with the paper recycling stream, and that it would be lighter, faster to pack, and more rigid. They said a better version of our product would have tighter tolerances, a more consistent fit, and a wider performance range. It should be cheaper, and it should also be available in even larger volumes. It should be natural, but not “too natural” – no dust or noticeable smell. Clean & consistent. And they wanted it nationwide.

So we went out to discover. After inventing and discarding several novel material concepts – we noticed that food snacks (like Cheetos, made from puffed corn) were lightweight, cheap, renewable and had surprisingly good insulating qualities due to their foam structure. They were water soluble. They also could be made anywhere and, being made of starch, possessed a natural adhesive quality. We invented insulation panels that combined paper with puffed corn starch to line the walls of a cardboard box. We named the new product “ClimaCell”. Today, ClimaCell (along with our Green Cell Foam product line) is being produced across the country, protecting millions of food shipments each week.

But we're still not satisfied with our products...

and will never be.

About 18 months ago, we again asked our customers to imagine a better version of packaging. Again – what would it look like? What would it allow them to do more effectively? This time, they didn’t describe a “faster horse”. They told us about the burden of receiving multiple truckloads a day of packaging insulation, and the pain of storage and inventory management. They told us about the challenge of multi-week lead times. In short, they didn’t tell us about a better version of packaging insulation, they lamented the fact that packaging insulation was necessary to begin with. This was key because, as Peter Drucker says, “Nothing is less productive than to make more efficient what should not be done at all”.

This is why we invented WaveKraft. It makes storage in a fulfillment center disappear.

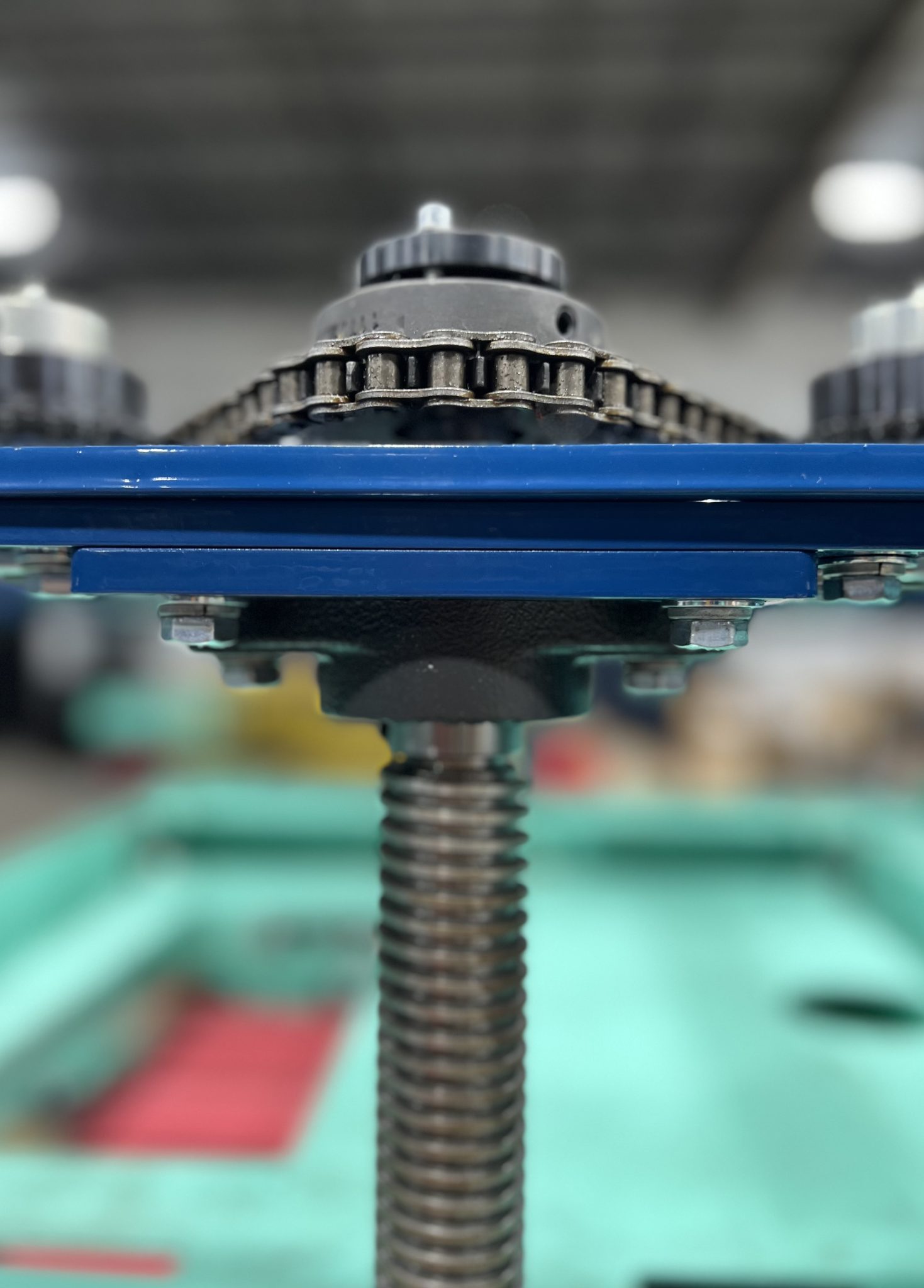

WaveKraft is made from paper and is easily recycled with the cardboard box that consumers get each week. WaveKraft is also made on a machine that is 99% smaller than a traditional manufacturing operation – meaning that customers can put a machine right on their floor. Using WaveKraft for a year, customers can avoid over 1,000 inbound trucks and reclaim 80% of the storage space that they currently use for packaging insulation. We’re excited to offer a solution that is not only cheaper, but far more versatile and easier to use than what’s available on the market today.

Had you told me in 2015 that we would have a team of 600+ spread across 4 manufacturing sites producing millions of sustainable packaging products each week I might not have believed you. But I’ve learned that growth happens when you relentlessly do what you feel you are unqualified to do. We’re excited to launch WaveKraft – and we’re excited to make it better. Our customers will always be the foundation of our drive to invent. Whatever we do, it’ll never be good enough – and that’s why I love going to work.

- James McGoff

Chief Product Officer

& Co-founder

TemperPack

WaveKraft

Our latest invention.

Designed for operations. Sustainable by design.

We believe the best packaging solution is one that uses the smallest amount of necessary material, can be stored as efficiently as possible, and can be easily recycled. We have always set these guiding principles when we develop new products, and WaveKraft is no different. If you’re ready to revolutionize your fulfillment operation, let’s talk.