Green Cell Foam™ is certified OK Home and OK Industrial by TUV Austria, the leading authority on compostable packaging. What does that mean? Here’s everything you need to know.

Who is TUV Austria?

TUV Austria is a global leader in providing industry best practices and certifications across safety, quality, innovation, and environmental protection, including product compostable certifications. TUV Austria’s clients, include leading enterprises and innovative companies across the globe, and countries such as France and Australia, base policies on TUV Austria’s guidelines.

Composting 101:

According to the EPA, composting is a “controlled, aerobic (oxygen-required) process that converts organic materials into a nutrient-rich, biologically-stable soil amendment or mulch through natural decomposition.”

A simpler definition: Composting is the natural process of recycling organic matter, such as leaves and food scraps, into a valuable fertilizer that can enrich soil and plants.

How does it happen? Microorganisms feed on the materials in a compost, using carbon and nitrogen to grow and reproduce, water to digest materials, and oxygen to breathe.

For composting can occur, three conditions are necessary:

- A balance of carbon-rich and nitrogen rich materials in a moist mixture.

- Oxygen-accessible environment.

- A high enough temperature to break down the materials.

What is the difference between ‘compostable’ and ‘biodegradable’?

According to the EPA, biodegradable means “ability of a substance to be broken down physically and/or chemically by microorganisms.”

When a product is biodegradable, it doesn’t necessarily enrich the soil or provide a foundation for new growth. All compostable products are biodegradable, but not everything that is biodegradable is compostable. Far from it. For a product to be compostable, it must biodegrade AND enrich the soil.

Home Composting vs Industrial Composting

Industrial Composting: Some materials, such as products or plastics made from starch, sugarcane, or agricultural waste, require temperatures nearing 55-60° Celsius to break down into compost. While not every US Metro area has easy access to industrial composting, many countries in Europe and Asia have well-established methods for collecting biowaste and creating compost in industrial sites. Products that can break down at the high temperatures achieved in an industrial composting site can earn the OK Industrial Compost label from TUV Austria.

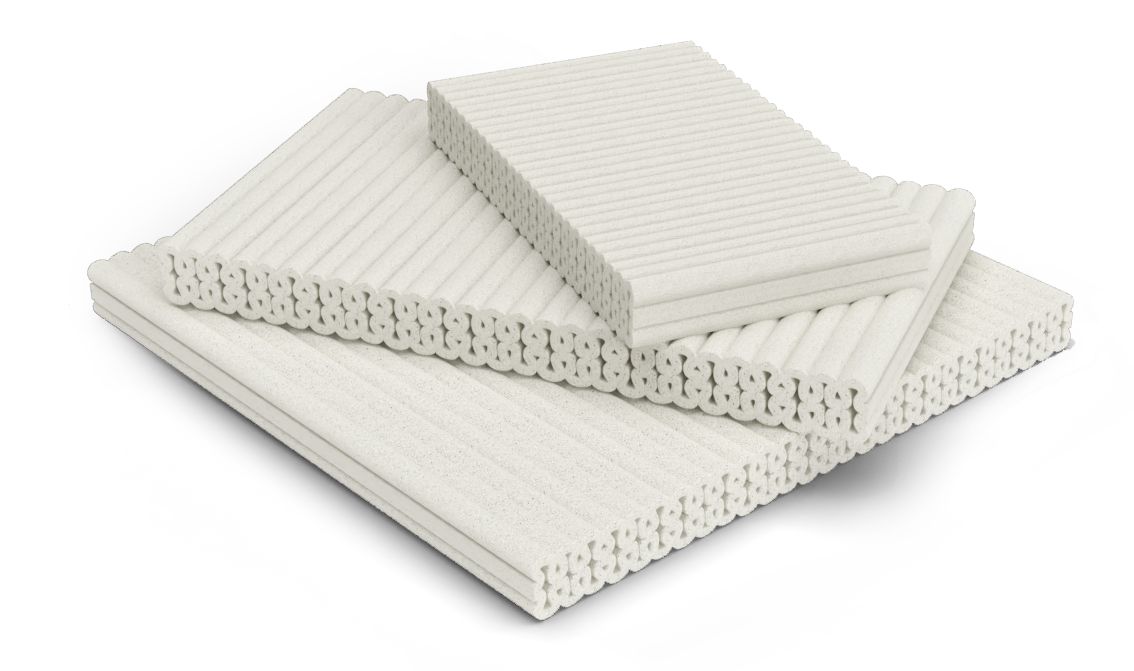

Home Composting: Some materials can be broken down in garden composts, without industrial-level temperatures, such as vegetable or fruit scraps. Green Cell Foam is such a material, with vegetable starch as its principle ingredient. Green Cell Foam breaks down in garden composts and carries the OK Home Compost Label from TUV.

While access to industrial composting through municipal programs is growing, home compostable certified products enable and encourage backyard composting in rural areas.

How does a product obtain the certifications?

TUV Austria follows the European Norm for compostable packaging—EN 13432. Under those guidelines, there are four material makeup tests that must be passed to receive certification. The tests are the same for both OK Home and OK Industrial.

To pass, the material needs to:

-

- Be broken down on a chemical level—biodegradation

- Be broken down on a physical level—disintegration

- Not release toxins upon breaking down—ecotoxicity

- Have a low heavy metal content

To prove the characteristics above, products must pass 3rd party lab testing that meets protocols established by the American Society for Testing and Materials (ASTM), specifically ASTM D6400 and ASTM 6868.

D6400: Specific to industrial compost certifications, often pertains to plastics and products made from plastic designed to be compostable. It tests and compares the material’s biodegradability rate to known compostables.

D6868: Designed for a broader category of materials, products, and packaging that are meant for industrial composting. The product must break down physically, have inherent biodegradability, and must decompose without damaging its immediate ecosystem.

When Compostable Waste Goes to a Landfill

When compostable waste goes to a landfill, it gets buried under massive amounts of other trash, cutting off a regular supply of oxygen for the decomposers. The waste then ends up undergoing anaerobic decomposition, being broken down by organisms that can live without free-flowing oxygen. During anaerobic decomposition, biogas is created as a by-product. This biogas is roughly 50 percent methane and 50 percent carbon dioxide, both of which are potent greenhouse gases, with methane being 28 to 36 times more effective than CO2 at trapping heat in the atmosphere over a century.

Although most modern landfills have methane capture systems, these do not capture all of the gas; according to the EPA, landfills are the third-largest source of human-generated methane emissions in the United States.

Guess what? Most of the material in a landfill could be composted. According to the EPA, “in the U.S., food is the single most common material sent to landfills, comprising 24.1 percent of municipal solid waste. When yard trimmings, wood and paper/paperboard are added to food, these organic materials comprise 51.4 percent of municipal solid waste in landfills.” We see this as a huge opportunity to improve how we handle waste and to create a lot more compost.

Reach out.

If you’re looking to improve your customer experience, bolster packaging performance, reduce total costs, or move away from plastic, we’d love to talk.