It's always been important to us to understand the impact of our packaging on the environment.

In our earlier years as a company, we made a good faith effort to estimate the impact of our ClimaCell thermal liners. We dove into data from utility companies, the U.S. Energy Information Agency, and available 3rd party databases such as the Greenhouse Gas Protocol. Our calculations in Excel were rigorous, but we knew we didn’t have the tools or expertise needed to produce an official ISO-compliant cradle-to-grave Life Cycle Assessment (LCA).

This year, that changed. TemperPack both obtained a SimaPro license and hired a sustainability analyst to build the single product LCA model and author the report. We also enlisted Long Trail Sustainability to conduct a concurrent critical review of both our model and report, in accordance with the 14040 and 14044 ISO standards (2006 a, b).

Why make this investment?

Well, according to co-founder and Chief Product Officer James McGoff, it was an easy decision. “Our company believes in doing the right thing, the right way, every time. One key step on that path is recognizing that data is king. Without it, it’s challenging (we’d go as far to say impossible) to assure continuous product improvement. We’ve long recognized the need to quantify the impacts of ClimaCell, and this year the time was right to take the next step to an ISO compliant model.”

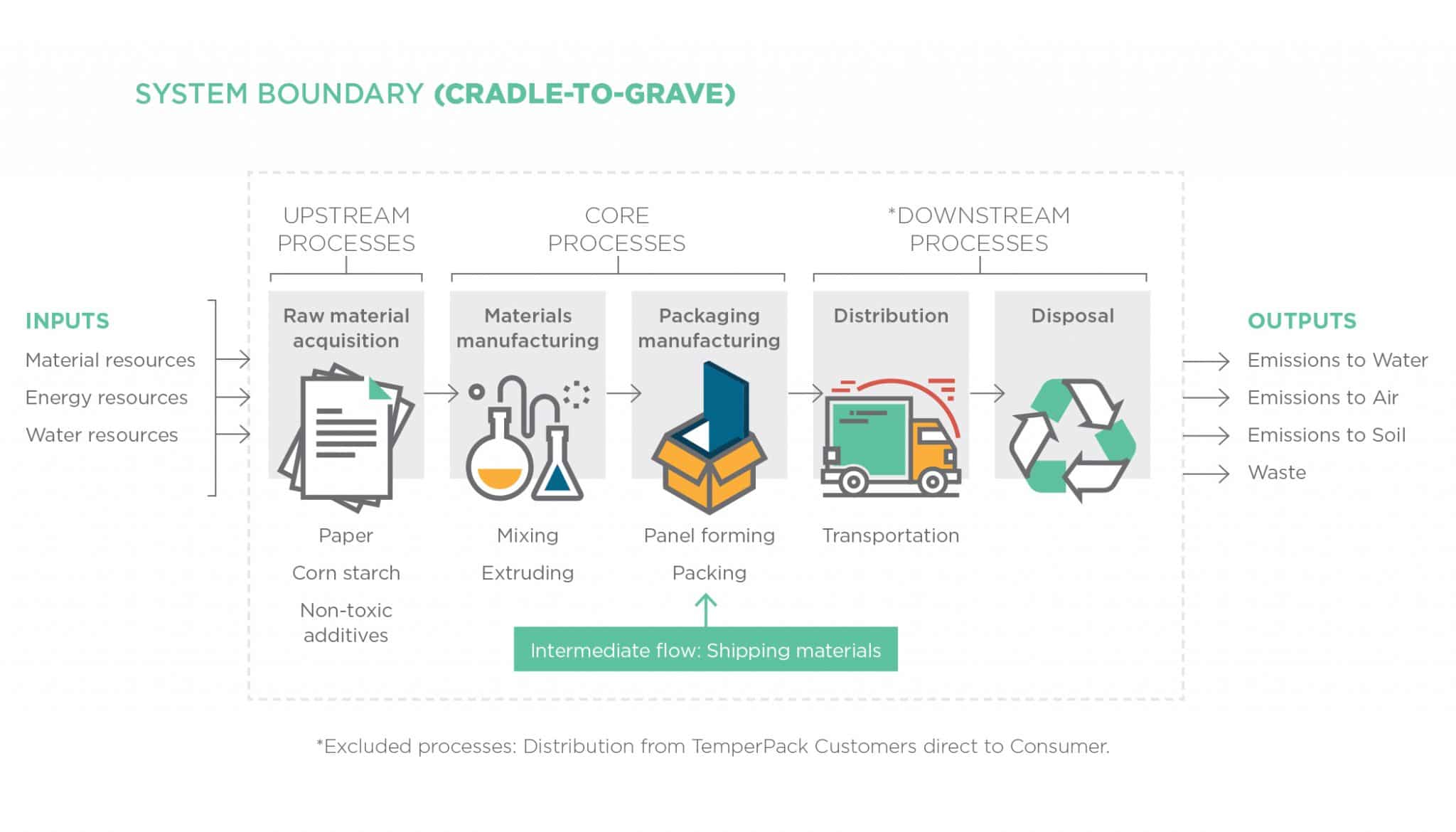

Below is a figure from the full report, demonstrating which processes within a ClimaCell Unit’s life cycle are included in the study:

The system boundary of this study reflects a cradle-to-grave study, encompassing upstream, core, and downstream processes.

Some of the findings?

Our Processes

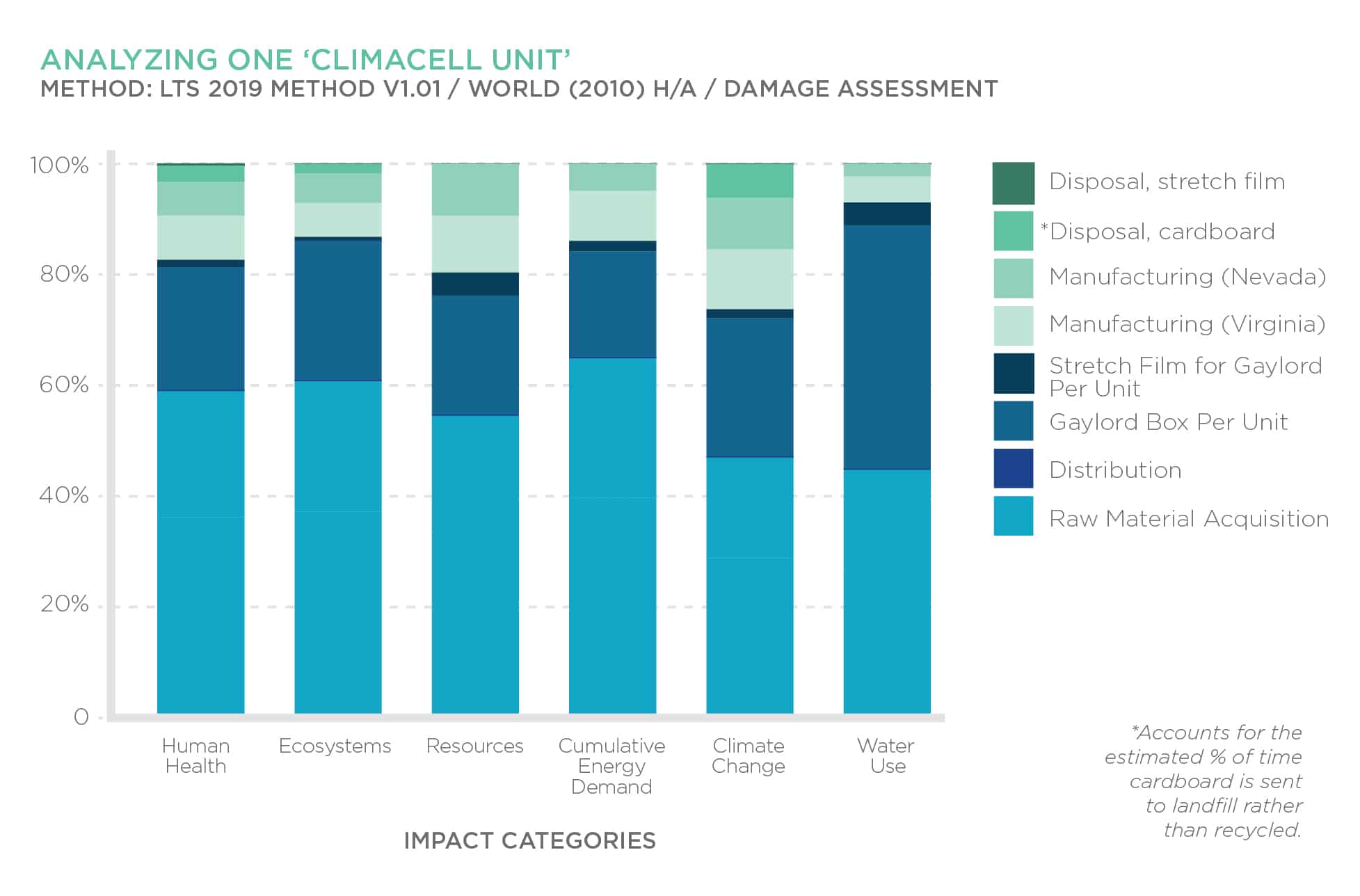

Our upstream processes, which include raw material inputs and the distribution of those materials to TemperPack, account for almost 50% of the total GHG emissions associated with producing a single ClimaCell Unit. Meanwhile, the downstream processes, which include the distribution of a ClimaCell Unit to its customers and the unit’s disposal, account for about 6% of the total CO2e produced. Here is a more detailed breakdown:

- Upstream Processes (raw material acquisition) – 47%

- Core Processes (manufacturing) – 20%

- Intermediate Flow (materials used to distribute our packaging - gaylords, plastic wrap) - 27%

- Downstream Processes (distribution and disposal) - 6%

Our Materials

When assessing a single ClimaCell insulation liner, results also show that our corn starch-based packing peanuts generate the greatest environmental impact across all the mentioned impact categories.

Our Energy

Of all the environmental impact categories assessed (Climate Change, Human Health, Ecosystems, Resources, Cumulative Energy Demand, and Water Use), Cumulative Energy Demand accounts for approximately 56% of the total environmental impacts of a single ClimaCell unit.

This report is just one step in our journey of environmental stewardship. This model gives us a better grasp of the environmental hot spots of a ClimaCell liner across its lifespan. It also gives our customers better information and more confidence about our packaging. More importantly, it provides benchmarks and insights we can use to optimize ClimaCell and develop new products.

The TemperPack team is committed to smarter packaging for a sustainable future. This study is just one step of many on that journey.