Think of all the items that require you to have a refrigerator and freezer in your home – i.e., meat products, dairy products. These are just a few of the many perishable foods we use everyday that are temperature sensitive.

For example, milk must stay in the refrigerator or else it will spoil. But have you ever thought about how milk remains at a safe temperature from the time it’s produced until you purchase it at the market? Temperature sensitive products require thermal shipping solutions and in this case what is called a “cold chain” to remain safe and/or viable for consumption or use.

Part 1

What is Cold Chain Shipping?

The term “cold chain” is a broad term used to describe a temperature-controlled supply chain. The cold chain requirements (i.e., acceptable temperature ranges) of one product may look completely different from those of another.

Managing cold chain logistics has always been complex, and those complexities are continuing to evolve with the growth of the eCommerce industry.

Traditionally, cold chain products have been moved in high volumes to a small number of destinations. Revisiting the milk example, the cold chain for moving thousands of gallons of milk from a dairy farm to a grocery store might look like this:

Load up a reefer truck

(a 53’ trailer specially designed to maintain refrigerated temperatures within)

Drive it to the store

Unload the milk into a refrigerated warehouse

(where it will get loaded into the display cases as needed.)

With the direct to consumer industry booming, consumers now have the option to buy their milk online, perhaps from a boutique dairy farm multiple states away. As you’d imagine, the cold chain for this model looks vastly different from the cold chain of the “traditional” milk model.

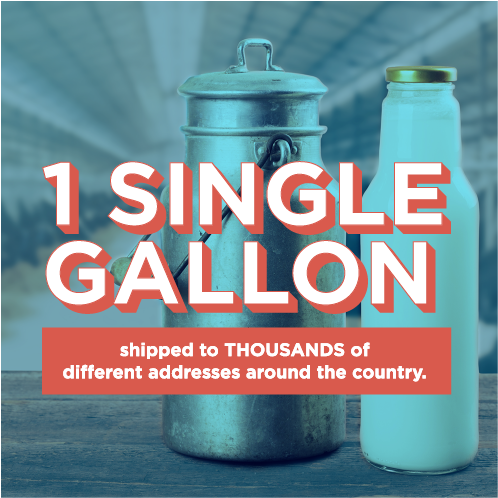

Instead of shipping thousands of gallons of milk each of a few grocery stores, this boutique farm might be shipping a single gallon of milk to thousands of different addresses around the country. While the cold chain requirements stay constant in both models (milk still has the same safe temperature ranges), managing the cold chain for the latter model is a very modern challenge that businesses of today are working on overcoming.

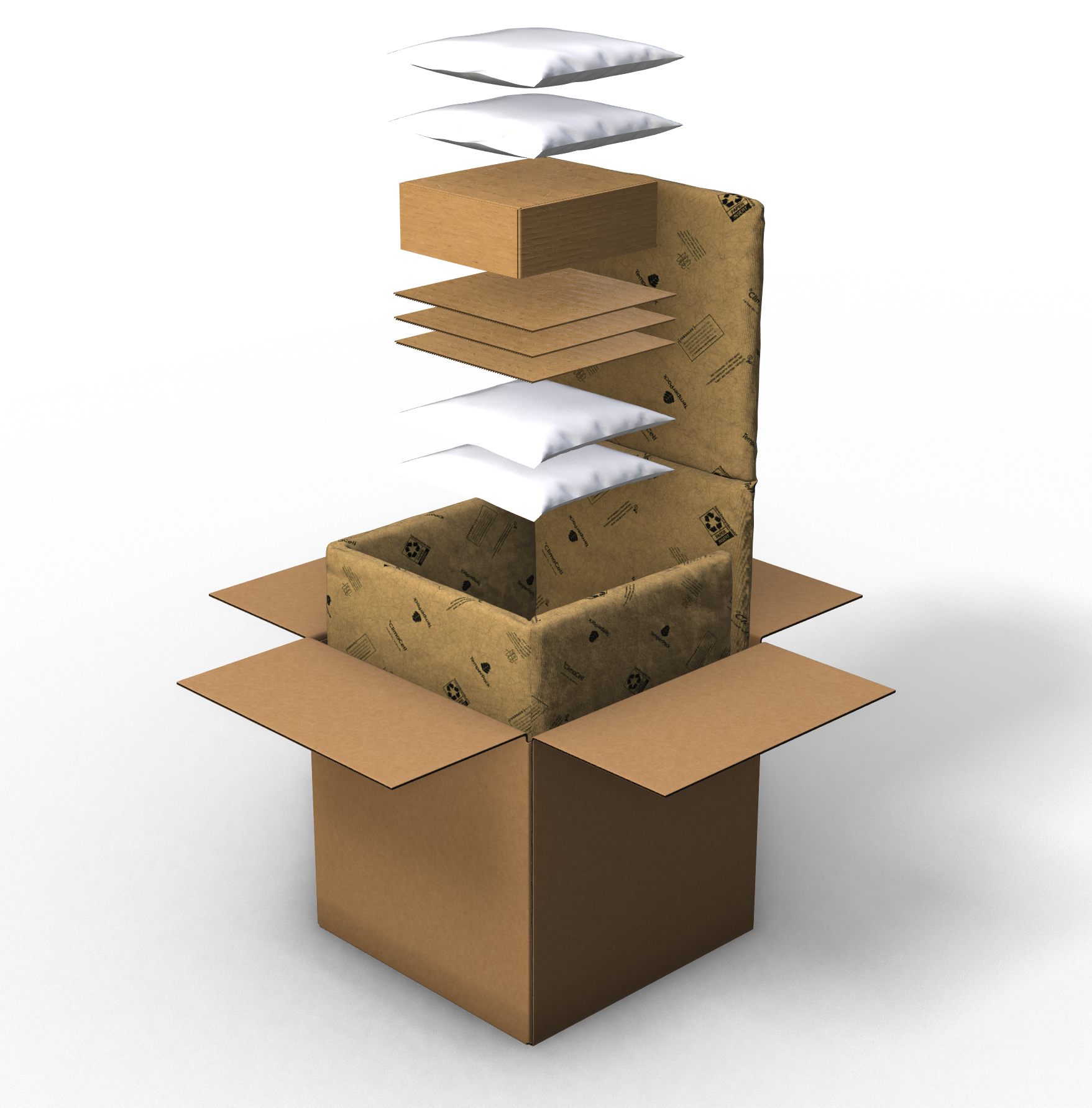

These B2C (business to consumer) cold chains require specialty packaging and other packaging components to ensure that product integrity remains intact during transit. We’ll spend the rest of this article digging into the factors, science, and examples of the cold chain shipping industry.

Part 2

Cold Chain Shipping Factors

Now that you’re aware that the world of cold chains exists, it’s important to know the basic factors you should consider when analyzing a cold chain and making decisions that might influence your product’s safety, integrity or the overall customer experience.

When cold chain shipping is boiled down to the basics, the following factors arise as the driving ones:

Acceptable temperature range

Above all else, the “safe” temperature range for the item(s) being shipped must be identified and considered when making cold chain decisions. This range may seem obvious for some products (i.e., – ice cream should remain below 0°F/-20°C), but for specialty products, such as pharmaceuticals or cosmetics, manufacturers make sure any temperature requirements are clearly listed on the product’s primary packaging.

Time in transit

Once you know the temperature that a product must maintain, you need to consider how long the cold chain packaging needs to do its job.

A local grocer offering free delivery/shipping might only need packaging that maintains the appropriate cold chain for a few hours, whereas a large meal kit company might need to maintain a similar cold chain for multiple days as the boxes are traveling hundreds of miles through a courier shipping network.

Ambient temperature

The last factor to consider is what external “forces” the shipment will face during transit. The packaging protecting a shipment occurring in Texas in August will often look different than the packaging protecting a similar shipment in New York in October.

Part 3

User Requirement Specification

All three of the above factors combine to form the foundation of what is referred to in the industry as a User Requirement Specification (URS). Selecting the appropriate “requirements” for your packaging is a balancing act between cost and risk level.

Let’s say it’s the holiday season and you’re shipping a cosmetic product between New York and several customers within the Northeastern US with a 1 day transit time. The cosmetics have been proven stable between 0°C and 20°C.

You have the ability to set your URS to the level of risk you want to take when shipping your product. In an extremely conservative case, you can say that you want the packaging to maintain a product temperature between 5°C and 15°C for 3 days, regardless of the outside temperature (warm or cold).

This URS would prevent any courier delays or any abnormal temperatures for the season from harming the shipment, but would also result in unnecessarily expensive packaging to accommodate the conservative requirements.

A more cost-effective URS might require the product temperature to stay between 0°C and 20°C for 2 days in Winter temperatures. This wider temperature range and shorter duration will result in less expensive packaging, but will still give you reasonable risk mitigation to account for unexpected delays during shipment.

Part 4

The Science of Thermal Shipping

The three factors discussed above all come into play when considering the science that drives the cold chain shipping industry—thermodynamics, a sub-discipline of physics that essentially governs how heat (energy) is transferred.

Thermodynamics is governed by four laws, the second of which is most important for our discussion

Sparing you the technical nuances, the important morsels to acknowledge are that:

Heat flows from hot to cold

Heat will continue to flow until

an equilibrium (balance) is reached

The 2nd Law states that heat moves. But how? Hundreds of years of thermodynamics studies have codified the transfer of heat into three modes:

- Conduction – heat moves directly from one object to another via physical contact (i.e., melting butter in a pan on an electric cooktop)

- Convection – heat passes from one object to another via a fluid (i.e, – the fan in an oven moves air which transfers the heat from the heating element to the food in the oven)

- Radiation – heat is transferred by electromagnetic waves (i.e., – the sun heats the earth via electromagnetic waves that are transferred through space)

Because it’s the form of heat transfer most relevant to thermal insualtion, let’s take a deeper look at Conduction…

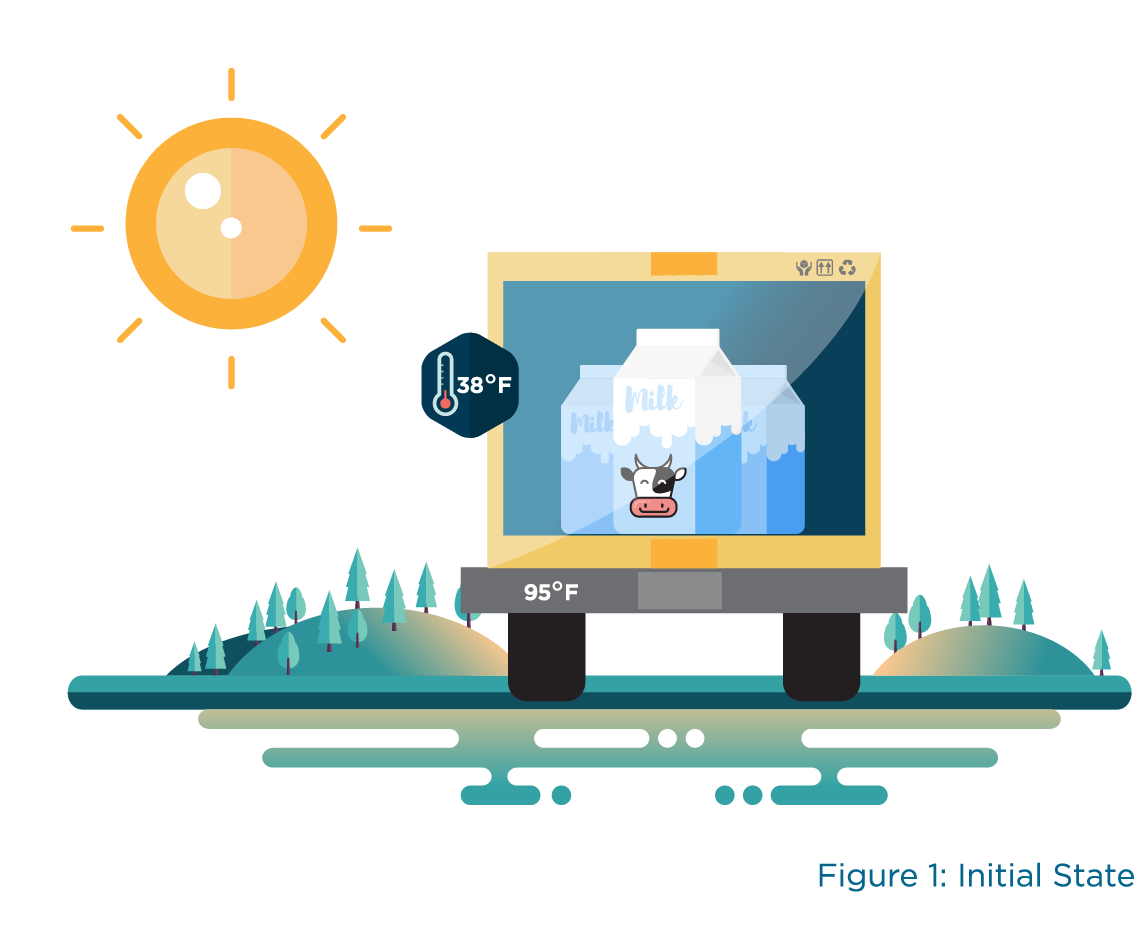

Let’s consider a cold chain shipping example where conduction is the primary mode of heat transfer. Figure 1, below, shows your gallon of milk freshly packed in an insulated box beginning its journey to the customer.

Since it’s summer weather, the bed of the truck is very hot.

As we learned from the 2nd Law of Thermodynamics, heat will flow from hot objects (the truck bed) towards cold objects (the milk) and will continue to flow until the temperatures reach an equilibrium (ie – both temperatures are equal).

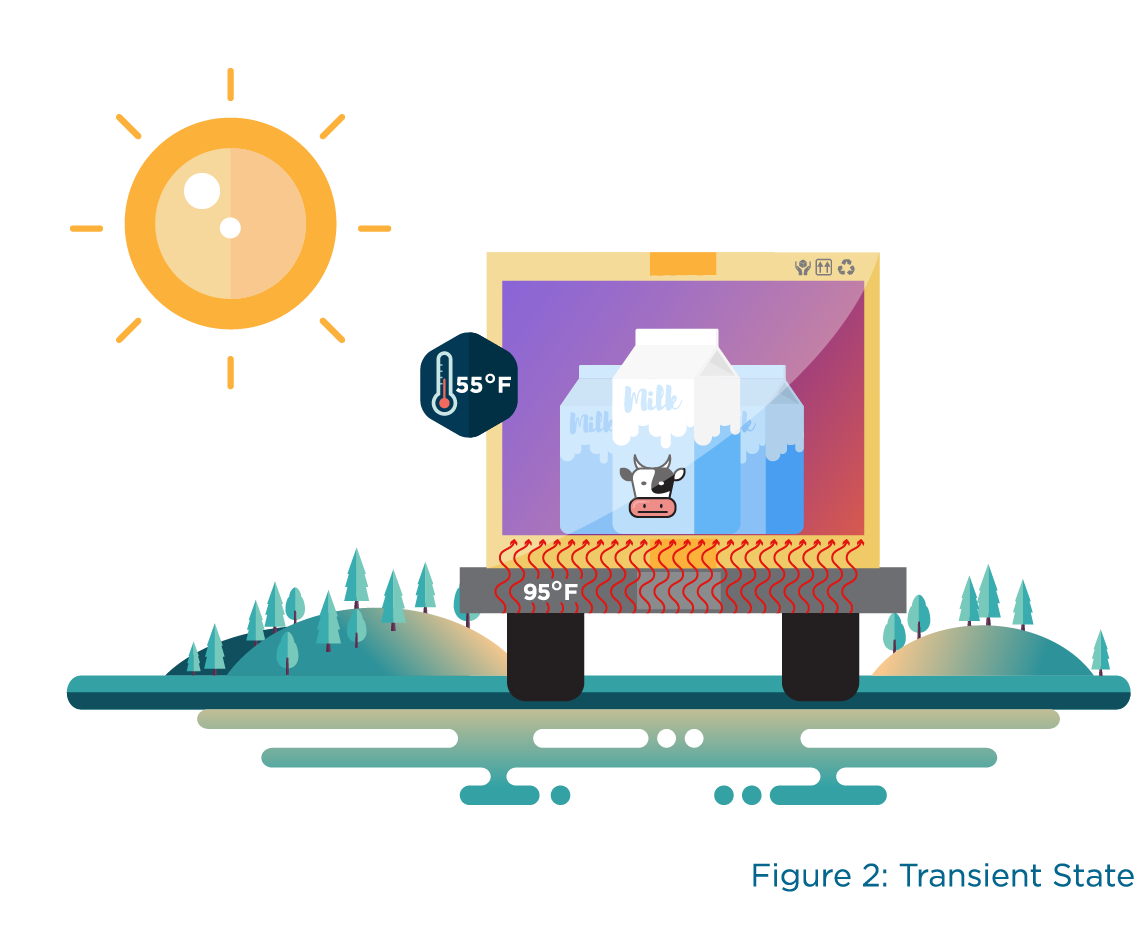

Figure 2, below, shows the heat being transferred into the box and gradually heating up the contents of the box.

Figure 3, below, shows the heat transfer ending because a thermal equilibrium across the box has been reached.

While this may seem like magic, scientists have distilled the transfer of heat via conduction down to this (simplified) equation:

Where:

- Q = Amount of heat transferred

- k = Thermal conductivity of the material transferring the heat. A highly conductive material will allow heat to flow through it very easily

- Thermal conductivity is an intrinsic material property of the insulation used to line the box

- FUN FACT: the inverse of thermal conductivity is thermal resistance (R-value!) and describes how good a material is at resisting the transfer of heat!

- A = area over which the heat is transferring

- The surface of the box in contact with the truck bed

- ΔT = difference in temperature across the material transferring heat

- 57 degrees (95 degrees – 38 degrees)

- x = thickness of the material transferring heat

- thickness of the insulation used to line the box

Part 5

More Cold Shipping Basics

Circling back to the basics, we know that heat is bad for your cold chain products, so you want to select packaging that will minimize the “Q” that is transferred from the ambient environment into the product being shipped.

Some of the variables in the heat transfer equation discussed above can be considered constants (or near constants) that you can’t tweak when managing your cold chain:

- ΔT – it’d sure be nice if you could control the weather, but since summer temperatures are always going to be hot and milk always has to stay refrigerated, you can’t simply minimize this variable to 0 and call it a day. Although that’s exactly what is happening when large dairy farms are shipping high volumes of milk directly to a grocery store! With the “outside” temperature also at refrigerated temperatures, there is no ΔT so no heat is flowing – it’s already in equilibrium.

- A – while you may have a little room to change your package’s size to reduce the area of the heat transfer as much as possible, you’re always going to be constrained by the size of the product you’re shipping so let’s consider this a constant as well.

That leaves you with two variables left for you to manipulate with your packaging decisions

- x – insulation thickness can be increased to slow down the amount of heat transferred into the product, but increases to insulation thickness often result in larger boxes (the extra “stuff” has to go somewhere and the product you’re shipping has a static size, remember?) so it’s not often an attractive option.

- k – this is where insulation makers make their money. Insulation with a low k-value (low conductivity), will not easily allow heat to conduct through it.

See? Cold chain shipping isn’t that bad. Once you identify your URS, you can apply those requirements to some basic thermodynamics equations and start making smarter decisions about your packaging.

We’re Here to Help.

Making the switch from traditional materials to sustainable and eco-friendly packaging is no longer a part of the distant future, but a current reality that companies must embrace to maintain a high ROI, nurture their stakeholder relevance and reduce their overall impact on our planet.

While it may not seem like an easy transition, sustainability in all aspects of your business begins with a commitment from you and all members of your company.

Michael Scipione

Michael Scipione is the VP of Product at TemperPack and leads the team's efforts in product develop, product testing, and intellectual property strategy. He is passionate about leveraging data and process in his work.

Michael holds degrees from North Carolina State University in Biomedical Engineering and Textile Engineering.

February 1, 2024

Cytiva and TemperPack: Pioneering Biotech’s Sustainable Packaging Revolution

In the biopharma industry, bold thinking and rigorous precision are needed to create new innovations for a healthier society. Cytiva is leading the field by forging a path towards…

January 4, 2024

Caroline’s Cakes and TemperPack: A Recipe for Sustainability

Caroline's Cakes, a staple in the Southern culinary scene, celebrated by Oprah, and Stephen Colbert, has partnered with TemperPack to reduce its environmental impact and improve…