Recyclability: Deep Dive

There’s no rulebook for recyclability. We’ve met with the leading organizations in the industry, including paper mills, waste collections companies, and materials recovery facilities (MRFs), to understand the pitfalls to avoid and assure our product is widely recyclable.

Step 1: Easy to Collect and Sort

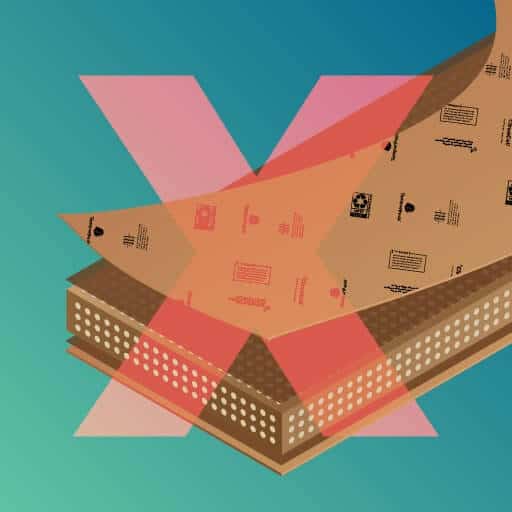

The first question is: “can ClimaCell panels be collected and sorted correctly?” ClimaCell panels are brown, flat, and rigid. This structure allows them to glide over star screens at Material Recovery Facilities just like cardboard, ensuring it sorts properly. How2Recycle, a program of the Sustainable Packaging Coalition, has given ClimaCell panels the “widely recyclable” Paper Insert designation.

Step 2: Useful Input for Manufacturing

The next question about recyclability is: “do paper fibers in ClimaCell liners provide valuable material in the making of new products?” The answer is Yes. In the repulping process the starch in ClimaCell dissolves and the useful fibers from the kraft paper are retained for use in new paper-based products.

In the Loop

We work closely with Closed Loop Partners, an investment firm focused on supporting and developing products and practices that support a circular economy to ensure that ClimaCell meets all the needs of both MRFs and paper manufacturer companies.

Sorting out Recyclability.

Ensuring a product is recyclable is not an easy task. Every Materials Recovery Facility (MRF) has their own opinions about what can and cannot be recycled. That’s why we worked with some of the largest national organizations to make sure our product meets the requirements of most of these facilities.

Step 1: Ensuring Proper MRF Sorting with How2Recycle®

The first step in the recycling process is making sure a product sorts with like materials. ClimaCell's primary material is kraft paper, which sorts alongside cardboard. It's flat design allows it to glide over star screens at Material Recovery Facilities just like cardboard, ensuring it sorts properly.

Step 2: Certified Repulpable by WMU's Pilot Plants Program

The final step in recycling involves 'can the material actually be reused after sorting?' In the repulping process the bio-based starch insulation inside dissolves and the useful fibers from the kraft paper are retained for use in new paper-based products.

Closed Loop Partners Backed

We worked closely with the Closed Loop Partners, an investment firm focused on supporting and developing products and practices that support a circular economy to ensure that ClimaCell meets all of the needs of both MRFs and paper manufacturer companies.

Composting

Let's talk about it.

ClimaCell liners are not compostable. Our goal in developing ClimaCell was to make a product that wouldn’t go to a landfill. When you look at the data, it’s clear that making a widely recyclable product is the best way to do that.

1300

Materials Recovery Facilities (MRFs) in the US.

100

Industrial Composting Facilities in the US

Recycling rate for corrugate waste in the US.

Composting rate for food and non-yard waste in the US.

Composting is great and we should do more of it. We will continue to explore compostable packaging in the future. When we developed ClimaCell, the data led us to recyclability as the best way to keep insulation out of landfills.

Taking on EPS.

Developing a replacement to EPS required us to develop a complete product that performs well, is affordable, and has a better environmental footprint.

End of Life

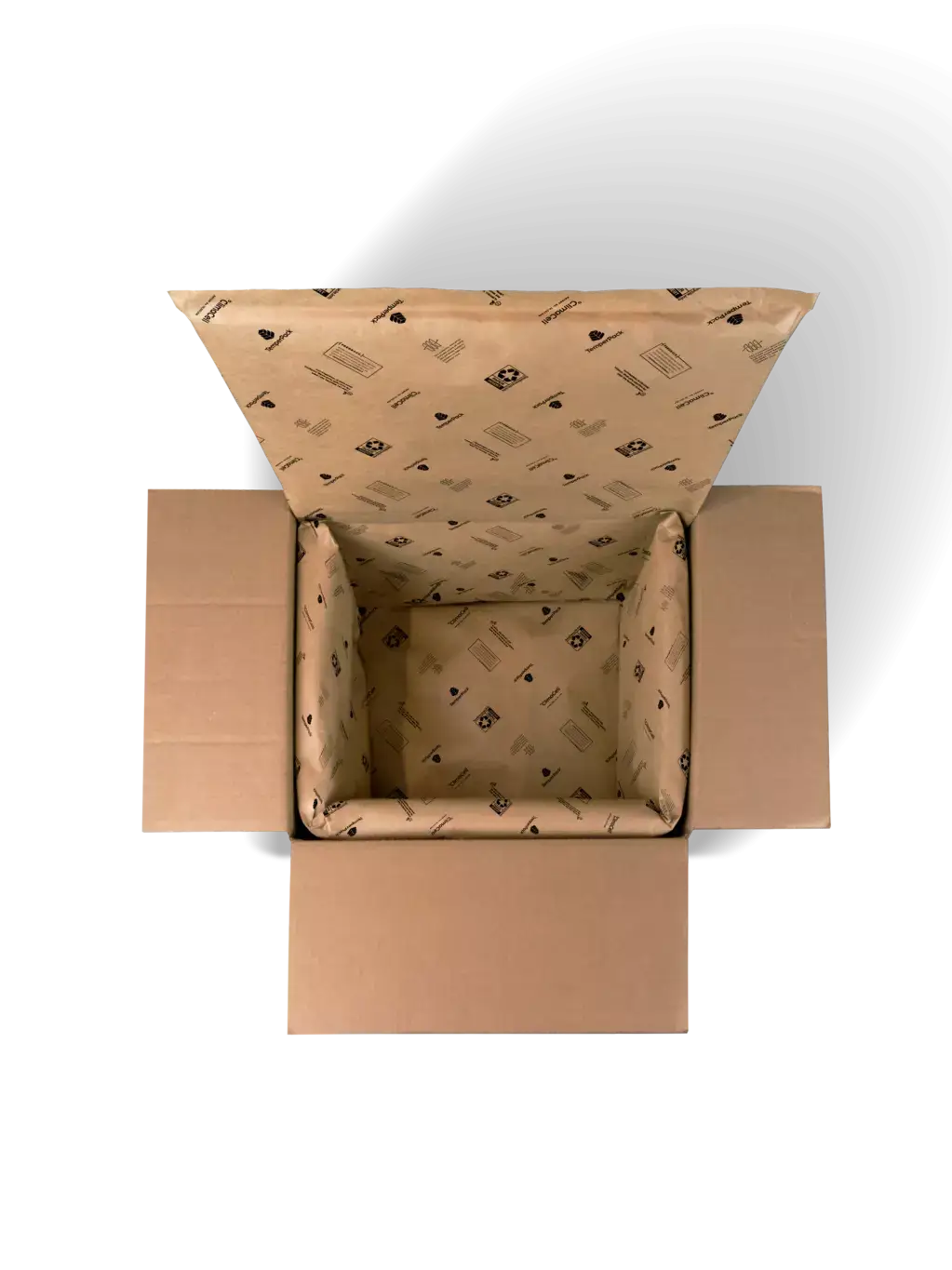

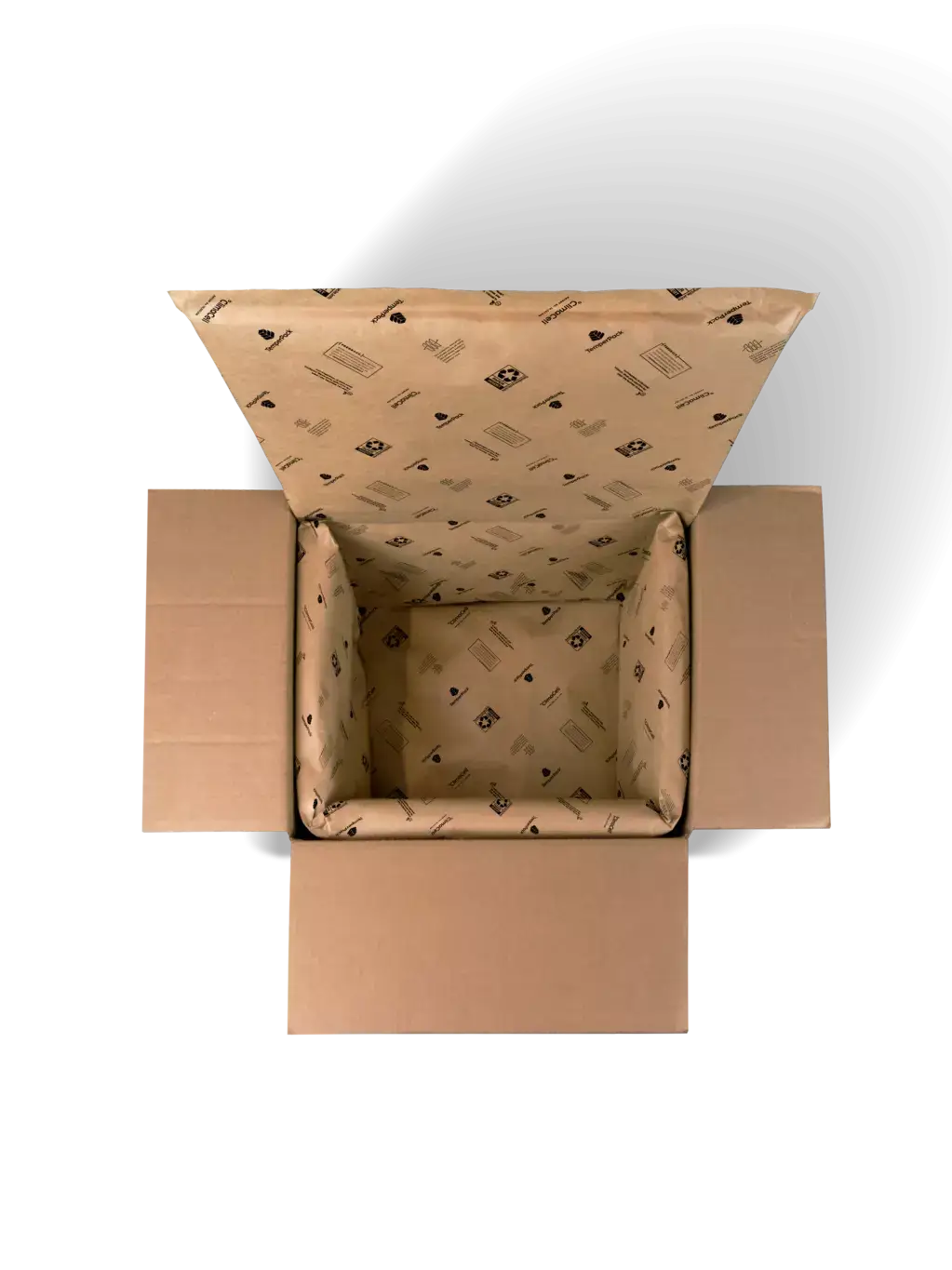

ClimaCell carries the 'Widely Recyclable' Paper Insert designation from How2Recycle®, which means it can go right your recycling bin, alongside the cardboard box it came in.

Reduced Emissions

According to information from our utility companies, EcoInvent database, and the Greenhouse Gas Protocol, we estimate that the manufacturing process used to produce ClimaCell reduces CO2 emissions by an average of 35% compared to Styrofoam.

Thermal Performance

The most important thing is for our customers’ shipments to arrive cold and safe. That’s why we’ve invested so much in our ISTA certified transport lab to prove that ClimaCell offers all the protection our customers need. ClimaCell has protected over 40 million shipments and counting.

At Scale

Developing high performance packaging with a top-flight environmental profile doesn’t do much good if it’s expensive and slow to manufacture. We are able to produce millions of liners per month, and that number is growing.

FAQs

Have more questions? Here are some answers to one's we get most frequently.

ClimaCell liners were not designed to be compostable and should not be placed in home composting or taken to industrial composting sites.

A ClimaCell panel is made with renewable paper and vegetable starch.

The panels also have a thin barrier coating and a few non-toxic ingredients to help them resist moisture.

We work with paper companies to source Forestry Stewardship Council (FSC) certified virgin kraft paper. This paper can stand up to the demands of a 48+ hour shipment, and the fibers in our paper can be recycled up to 5 times.

While the recycling industry has been going through changes since the China ban of 2018, recycling is still very important. Bales of post-consumer paper are a vital input in the paper-making process for mills in the US and abroad. When a paper product is recycled, it helps reduce the number of trees needed to make the paper we all use every day.

Yes. This barrier coating has been on the paper for our testing at Western Michigan University. Conversations with several paper companies and this guide from the AF + PA affirm that the layer does not pose a problem in the recycling process.

Nope. We’re gluten free, soy free, dairy free, and free from animal products.

ClimaCell liners are beautiful and non-toxic, but they are not meant to be eaten. Please don’t eat them.

Due to the demands of the cold chain process, they cannot be re-used as insulation for e-commerce shipments.

Truly the best thing is to put the panels back into the recycling stream so the paper fibers can be used to make new paper.

Since ClimaCell is a new material, some waste collection and recycling organizations don’t recognize it. Please fill out the form at the bottom of this page with their information and we’d love to talk to them.

If you received a ClimaCell shipment:

Proper disposal is key to ensuring packaging ends up in the right place. We currently manufacture ClimaCell in a couple of different ways, so we want to make it clear how best to dispose of each version of the product.

If it’s wrapped in paper...

just put the whole panel (paper encapsulation and interior panel) in your recycling bin.

If it’s wrapped in plastic...

remove the plastic and recycle it along with plastic grocery bags (it’s a #4 plastic). Then you can put the interior panel in your recycling bin.

If you want to compost it at home...

we’re currently in the process of getting our compostability certification from outside experts. If you want to try it, first remove the encapsulation, as the paper encapsulation has a moisture barrier on it which will not compost.

Get in touch

We developed ClimaCell to be the best curbside recyclable alternative to expanded polystyrene foam (also known as Styrofoam®). We’re engineers at heart and are always working to improve our products. If you have feedback or questions for us, please leave us a message.

FeedbackCommentsQuestionsPraiseObservationsCriticisms

Your feedback matters.

We're trying to build the best packaging company on Earth. In order to do so, we need to know what's working, and what's not. Please use the form below to let us know how your experience with our product has been.