ClimaCell® is our patented flagship material made from renewable plant-based components and paper. With excellent thermal performance and a competitive cost structure, it is the ideal replacement for unsustainable insulators, like Styrofoam®. ClimaCell represents our understanding of the insulation market and seeks to improve the category by pushing it toward a more sustainable future.

There are a lot of recyclable materials out there. Unfortunately, most of them end up in waste streams that don’t get reused. We designed ClimaCell to be repulpable alongside cardboard, a product that is recycled 93% of the time. You can check out our recyclability study here. We’ve worked with third party consultants to ensure that ClimaCell is OCC-E certified curbside recyclable and that it passes Materials Recovery Facilities tests to be reclaimed alongside cardboard.

ClimaCell is registered patented no. 10,357,936 under the United States Patent and Trademark Office.

Only 9 percent of all plastic is ever recycled. Scientists estimate that by 2050, there will be more plastic than fish in Earth’s oceans.

Conversely, 93% of corrugated material is recycled and can be reused to make more paper products up to 7 times, making it the most reusable consumer-based material in the world.

Sorting out Recyclability.

Ensuring a product is recyclable is not an easy task. Every Materials Recovery Facility (MRF) has their own opinions about what can and cannot be recycled. That’s why we worked with some of the largest national organizations to make sure our product meets the requirements of most of these facilities.

Step 1: Ensuring Proper MRF Sorting with How2Recycle®

The first step in the recycling process is making sure a product sorts with like materials. ClimaCell's primary material is kraft paper, which sorts alongside cardboard. Its flat design allows it to glide over star screens at Material Recovery Facilities just like cardboard, ensuring it sorts properly.

Step 2: Certified Repulpable by WMU's Pilot Plants Program

The final step in recycling involves 'can the material actually be reused after sorting?' ClimaCell is certified repulpable by Western Michigan University's Pilot Plants Program using the OCC-E testing protocols laid out by the Fibre Box Association and the American Forest & Paper Association. In the repulping process the bio-based starch insulation inside dissolves and the useful fibers from the kraft paper are retained for use in new paper-based products.

Closed Loop Partners Backed

We worked closely with the Closed Loop Partners, an investment firm focused on supporting and developing products and practices that support a circular economy to ensure that ClimaCell meets all of the needs of both MRFs and paper manufacturer companies.

Sorting out Recyclability.

Ensuring a product is recyclable is not an easy task. Every Materials Recovery Facility (MRF) has their own opinions about what can and cannot be recycled. That’s why we worked with some of the largest national organizations to make sure our product meets the requirements of most of these facilities.

Step 1: Ensuring Proper MRF Sorting with How2Recycle®

The first step in the recycling process is making sure a product sorts with like materials. ClimaCell's primary material is kraft paper, which sorts alongside cardboard. It's flat design allows it to glide over star screens at Material Recovery Facilities just like cardboard, ensuring it sorts properly.

Step 2: Certified Repulpable by WMU's Pilot Plants Program

The final step in recycling involves 'can the material actually be reused after sorting?' ClimaCell is certified repulpable by Western Michigan University's Pilot Plants Program using the OCC-E testing protocols laid out by the Fibre Box Association and the American Forest & Paper Association. In the repulping process the bio-based starch insulation inside dissolves and the useful fibers from the kraft paper are retained for use in new paper-based products.

Closed Loop Partners Backed

We worked closely with the Closed Loop Partners, an investment firm focused on supporting and developing products and practices that support a circular economy to ensure that ClimaCell meets all of the needs of both MRFs and paper manufacturer companies.

Performance

Inch per inch, ClimaCell performs as well as expanded polystyrene (EPS) and denim fiber insulation. Our unique manufacturing process also allows us to vary the thickness of ClimaCell based on seasonal performance needs.

Box Dimensions

14.25″ x 10.75″ x 13.75″

Packout

Three (3) 3LB gel packs, 1 32ECT zone separator, and a 1-inch 2PC with ClimaCell liner.

Packouts were tested using TR-71WF temperature loggers in SM-32C and SM-16C Thermotrons using an 80-hour Summer heat profile.

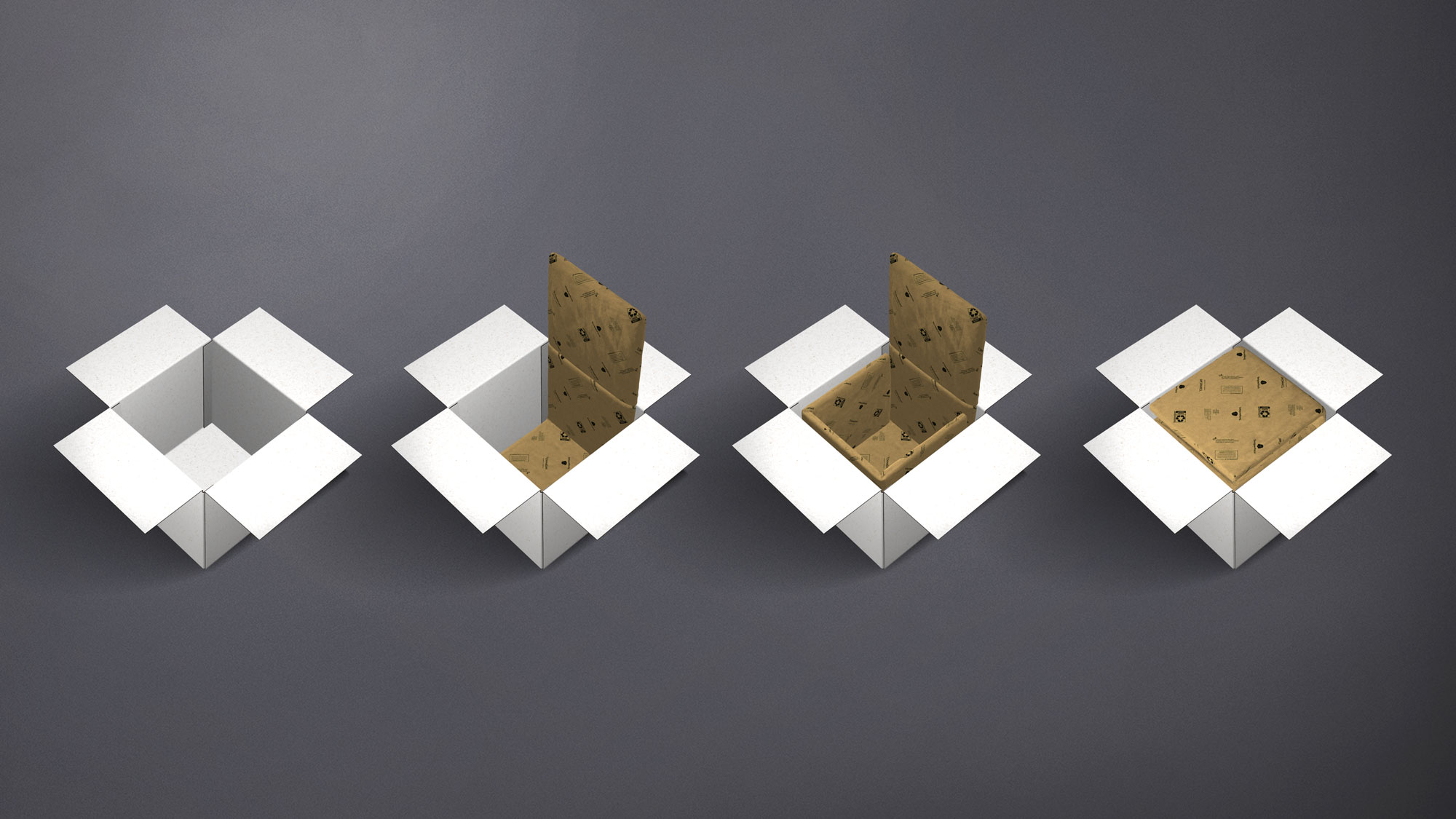

Ships Flat. Saves Space.

Unlike rigid Styrofoam coolers, ClimaCell box liners ship and store flat until you’re ready to use them, saving you on freight costs and warehouse space in your facility. Assembling an insulated shipper is extremely easy.

Distribution Partners