2019 Impact

Our mission is to protect products with packaging that protects the earth. 2019 was a great year for advancing this mission.

Our packaging protected over 19 million shipments in 2019. Since we were founded, that total is over 40 million. Last year, over 60 companies started using ClimaCell for thermal insulation, bringing our total customer count to over 100.

Those companies chose ClimaCell for its strong thermal performance, its potential to reduce overall shipping costs, the ingenuity and perseverance of our teams, and, of course its environmental sustainability.

We believe ClimaCell is the best performing, most environmentally friendly way to ship control room temperature (CRT), fresh, and frozen items.

Part 1

End of Life

Great product design starts with planning for what happens to it after it has served its purpose. We designed ClimaCell to be the first curbside recyclable high-performance thermal insulation, to keep waste out of landfills and give the raw materials another purpose.

Last year, by using ClimaCell instead of expanded polystyrene insulation (EPS), we estimate that our customers diverted over 3 million cubic feet of plastic foam out of landfills. That’s over 34 Olympic swimming pools.

Part 2

The Right Ingredients

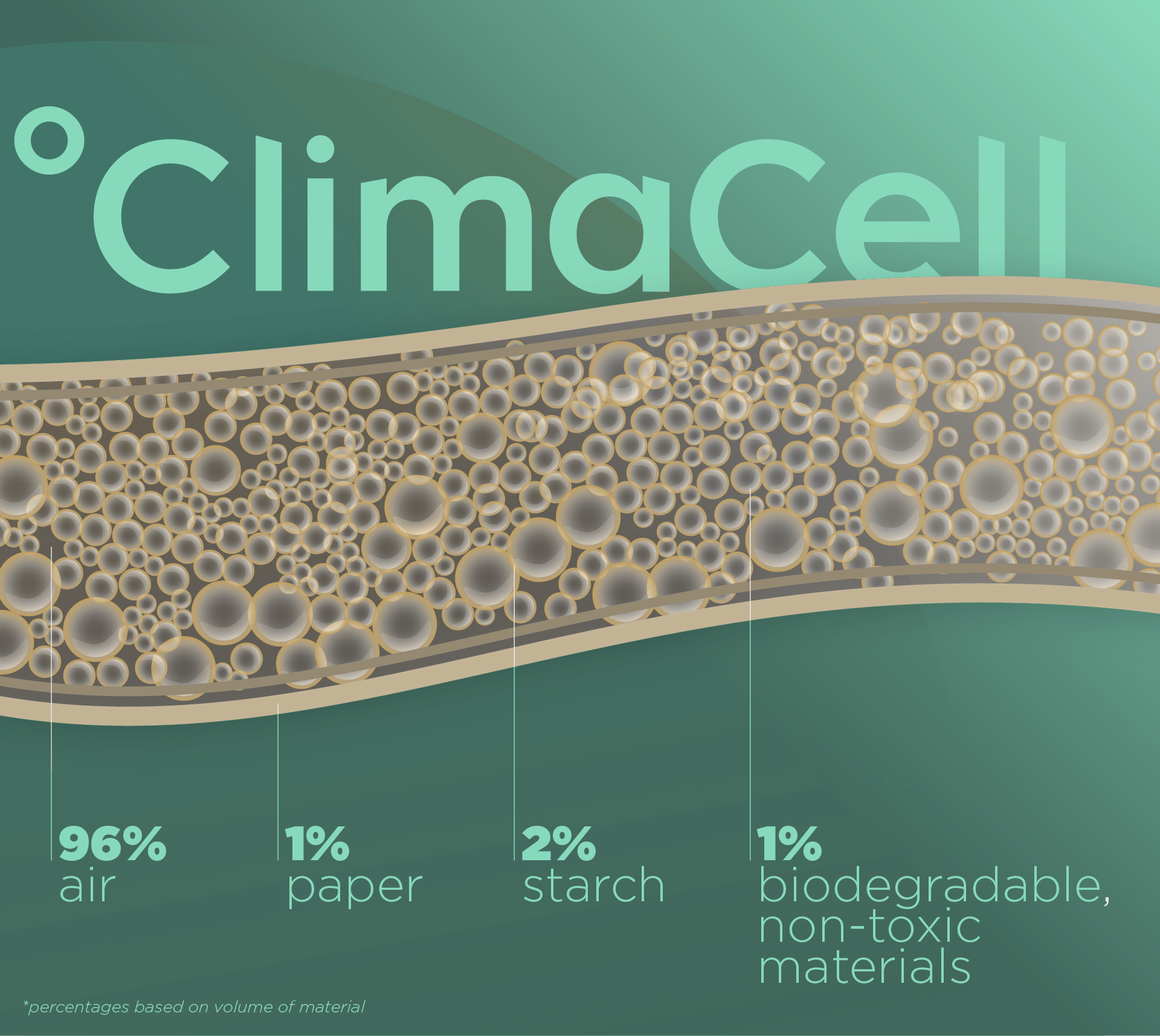

We’re proud of our materials:

Our first product, Fiber, used re-purposed jute and cotton liners as the primary source of insulation. This gave second life to material that would have gone to the landfill.

When we designed ClimaCell, we made a purposeful choice to start with renewable, plant-based materials. This is not only good for the environment but allows for traceability and assures our supply chain will be secure. By volume, ClimaCell is over 99% air, paper, and starch.

Part 3

Manufacturing Emissions

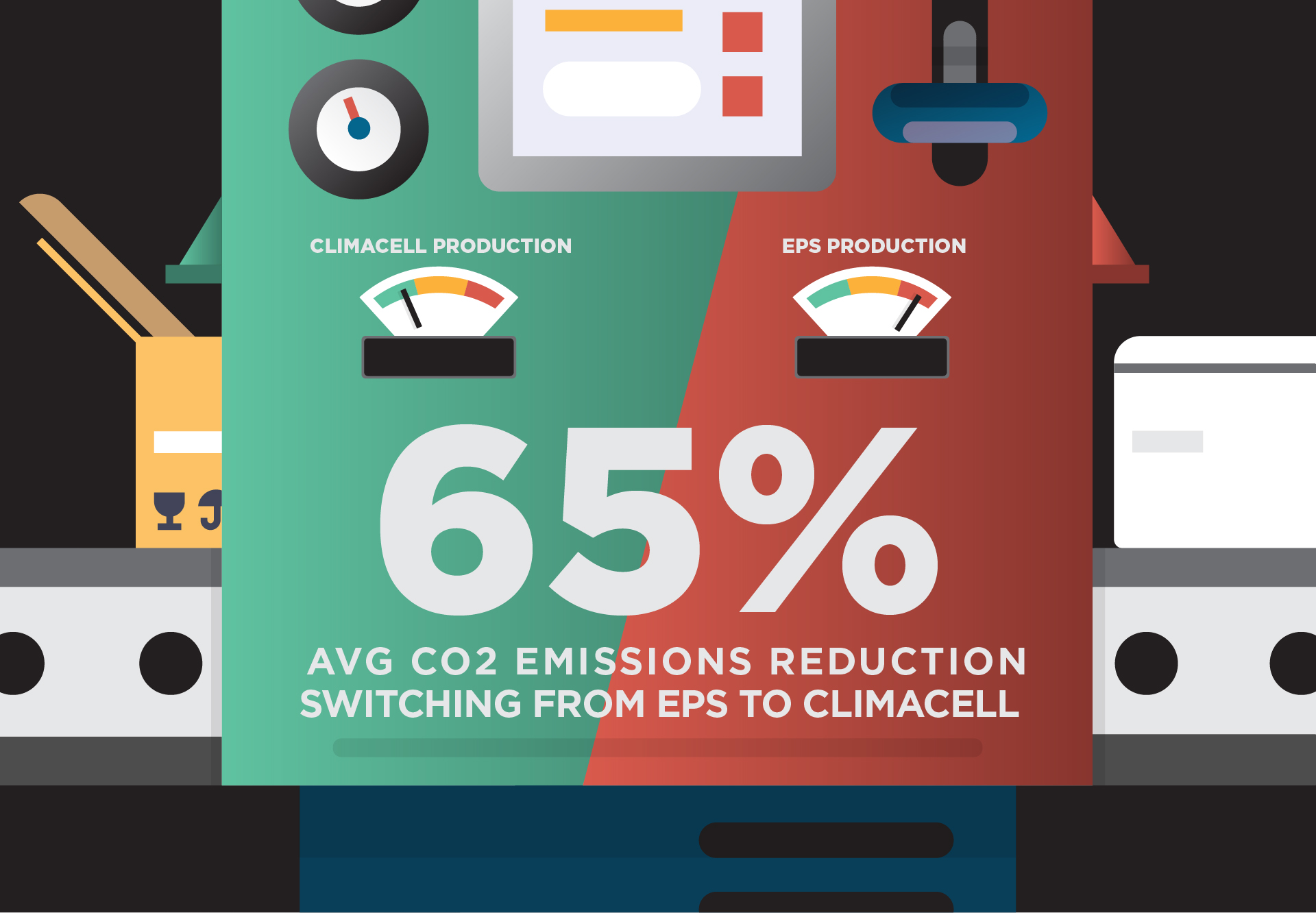

We developed a custom manufacturing process to maximize output with as much speed and as little energy as possible. This not only reduces our carbon footprint but also allows us to compete at scale with plastic materials.

This year, we reviewed our production output and our energy use in Richmond and Las Vegas, including our corporate offices, as well as data from:

- Dominion Energy

- Nevada Energy

- US Energy Information Administration

- Greenhouse Gas Protocol

- EcoInvent Database

Using this data we were able to calculate estimates of the per-unit carbon dioxide emissions associated with manufacturing ClimaCell and of EPS.

Part 4

What does this mean?

In 2019, by using ClimaCell instead of EPS, we estimate that our customers avoided the creation of over 16,000,000 pounds of CO2 emissions. That’s like:

1,577

Cars removed from the road for one year.

120,667

Trees planted and let grow for 10 years.

2,547,945

Cell phones charged for an entire year.

277,232

Incandescent light bulbs switched to LED.

Work With Us

We’ve helped dozens of companies reduce their packaging costs and lower their overall impact on the environment. Give us a shout and we’ll work with you to develop a solution that suits your shipping needs.

John Briney

John Briney is the Director of Marketing at TemperPack. Before joining the team, he worked in a number of advertising agencies in New York creating work for brands big and small. He has a post-graduate degree in advertising from the VCU Brandcenter.

February 1, 2024

Cytiva and TemperPack: Pioneering Biotech’s Sustainable Packaging Revolution

In the biopharma industry, bold thinking and rigorous precision are needed to create new innovations for a healthier society. Cytiva is leading the field by forging a path towards…

January 4, 2024

Caroline’s Cakes and TemperPack: A Recipe for Sustainability

Caroline's Cakes, a staple in the Southern culinary scene, celebrated by Oprah, and Stephen Colbert, has partnered with TemperPack to reduce its environmental impact and improve…